A mini excavator is used on construction sites for many tasks, such as digging, grading, and lifting. However, if not maintained and operated well, it can result in many kinds of breakdowns, may face various repairs, and cause a slow down in working speed. That is why proper operator training is important. It helps you keep things safe while at the same time ensuring you are getting the most out of that machine.

Knowledge of operation and maintenance will go a long way in ensuring the mini excavator has a longer period before it develops a fault and consequently reduces downtime. For newcomers, information from such resources as Machines Wiki Machines Wiki will be helpful.

Now, let’s try to discover the basics of becoming proficient operators of mini excavators.

Basic Controls and Operations of a Mini Excavator

The initial requirement of mini excavator operation is learning the controls. While controls may vary slightly between models, the general layout remains consistent:

- Joysticks

- The two joysticks operate the boom, stick, and bucket. Traditionally, one slides the arm up and down while the other handles the side-to-side and bucket swings.

- Foot Pedals

- For additional purposes, for example, to actuate attachments or to turn a cab.

- Travel Levers

- These are positioned on the seat’s lower side, at the operator’s feet, and they manipulate the machine’s motion because they are also used to move the machinery.

- Throttle and Gauges

- The accelerator controls the amount of power an engine produces, and the indicators indicate the level of fuel and the temperature.

- Safety Features

- A few safety features to make acquaintances with include the emergency shutoff switch and backup alarms.

After becoming familiar with the controls, use the RC in an open area to create muscle memory for operating it.

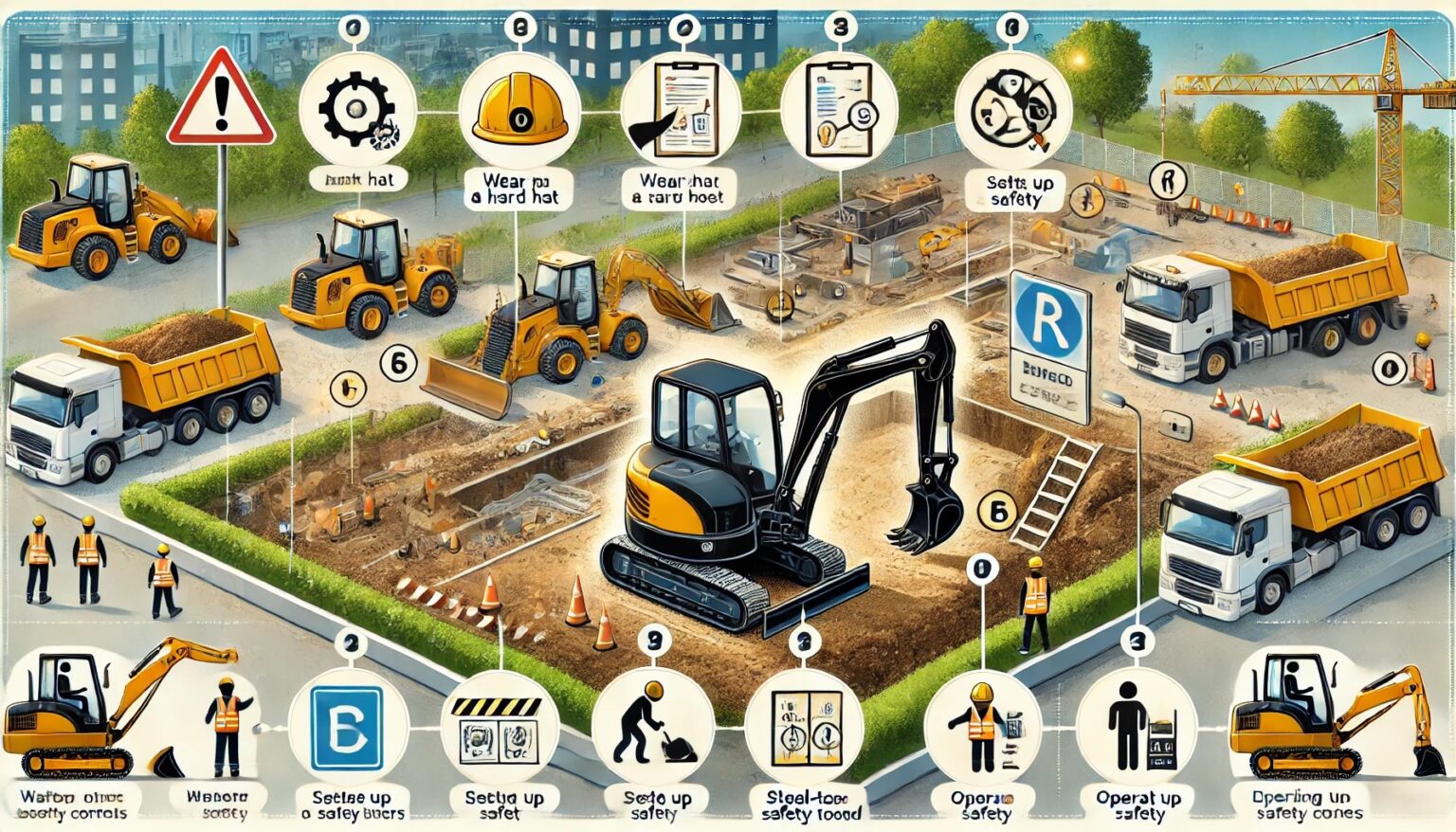

Safety Tips for Mini Excavator Beginners

The use of mini excavators requires a lot of safety measures, especially for new users. Here are some essential tips to keep in mind:

- Wear Proper Gear

- Always wear a hard hat, steel-toed boots, and other reflective clothing to be safe and conspicuous at the workplace.

- Inspect the Machine

- Be Aware of Surroundings

- Ensure you look out for obstacles or any object in your way ahead, such as power lines or land that is not suitable for the operations.

- Secure the Area

- Use barriers or cones to section off the area and ensure that people do not approach within a dangerous distance.

- Maintain Stability

- Avoid overloading the bucket and always transport the load close to the floor.

- Use Seatbelts and Safety Locks

- Secure yourself up and ensure that the seat belt is draped over you in order to minimize movement in any direction.

Following the stated measures, reducing the level of risks and providing a safe working environment is possible.

How to Handle Common Challenges During the Operations

Operating a mini excavator is not without its challenges, but understanding how to address them can make all the difference:

- Uneven Terrain

- Solution: Do not overload and take time when lifting something. If possible, then use stabilizers to provide extra support.

- Stuck in Mud

- Solution: The bucket must be used by the operator to push or pull the machine out. DO NOT spin the tracks, as this will aggravate the problem.

- Limited Visibility

- Solution: To work in these areas efficiently, mirrors or videos should enhance visibility.

- Solution: To work in these areas efficiently, mirrors or videos should enhance visibility.

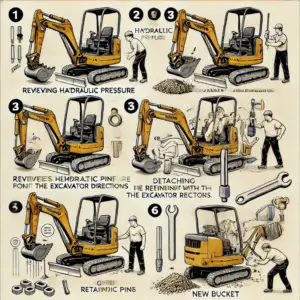

- Attachment Issues

- Solution: Attachments must be properly attached and fit the machine in question, as different kinds of attachments can have different requirements. High-quality attachments, such as those available from USA Excavator, can simplify this process.

- Hydraulic System Problems

- Solution: Hydraulic fluid should be checked frequently, and fluids should also check hydraulic hoses for signs of leaks or deterioration.

Fortunately, these are issues that, with experience and preparation, help to deal with effectively.

Maintenance Knowledge Every Operator Should Have

Recognizing fundamental repair is essential knowledge among mini excavator operators. Here are some key areas to focus on:

- Daily Inspections

- For now, the realization and measurements include checking engine oil, hydraulic fluid, and coolant levels and inspecting the tracks, attachments, and hoses for signs of wear or damage.

- Filter Replacements

- Replace your air and fuel filters as per the manufacturer’s advice or when they become dusty or dirty.

- Lubrication

- Lubricate any moving concrete part as often as possible, such as the grease pivot points on the swing bearings and other parts.

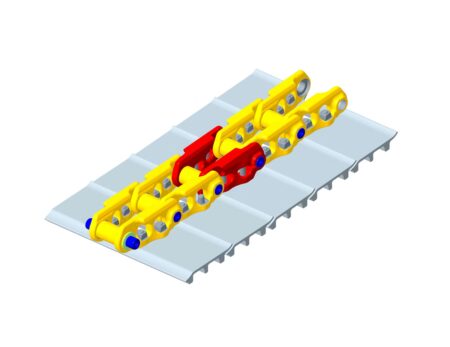

- Track Tension

- Make sure that the tracks are tight. The wheels tend to derail if they are loose, while if they are too tight, they quickly wear out.

- Seasonal Adjustments

- Engine block heaters and antifreeze are recommended for winter. The cooling systems should be cleaned and tested before summer.

For other specific types of maintenance information, please refer to Machinery Asia.

Best Practices for Maximizing Efficiency with a Mini Excavator

Timely delivery and costs are determinants of successful work output. Here are some tips to get the most out of a mini excavator:

- Plan Ahead

- Survey the terrain of a project and define any hindrances that can be encountered during the course of the work.

- Use the Right Attachments

- Upgrade the mini excavator for certain uses with machines such as grading buckets for levelling and hydraulic breakers for demolition.

- Practice Precision

- Do not dig or work incessantly or rush around frantically, as this is time-consuming and wastes fuel.

- Optimize Machine Settings

- Use throttle weights according to the application to save fuel and prevent erosion.

- Stay Updated

- Concentrate on practising the recent technological advancements in the technique to enhance the profession’s ability.

The following practices will help achieve this goal of enhancing operational efficiency and, in the process, reducing costs.

Conclusion

Learning to drive a small digger well takes time, practice, and dedication. However, if you learn the basics, prioritize safety, and perform regular maintenance, you can feel more confident in your job and do a great job at it.

Explore trusted suppliers like TYPHON Machinery, USA Excavator, and Machinery Asia for reliable equipment, attachments, and maintenance support. However, other related tools, such as Machines Wiki, exist to gain more understanding.

With proper education and equipment, one can become an experienced operator who will guarantee that each project is accomplished successfully and without failures or injuries!