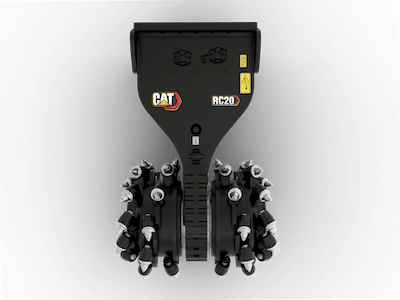

Caterpillar introduced two new rotary cutter attachments for demolition and controlled trenching in confined spaces at ConExpo-Con/Agg 2023.

Not as loud as other breaking tools, rotary cutters create a more controlled breaking with high precision making them ideal for working in confined or urban areas.

The new Cat RC20 and RC30 models are available to be used with pin-on, S-type, Cat pin grabbers, or CW couplers.

Tom Munch, Caterpillar applications specialist, noted that the numbers in the nomenclature represent the low end of the machine size in tons that the tools are meant to be attached to. “Your RC20 is going to go on 320s through 330s, and the RC30 is going to be hooked to 326 up to 340,” he said.

Munch noted that in the Q1 of 2024, Cat will release additional models to fit the 311 to 320 and 340 and up to complete the excavator offerings.

“To me, the most important specs within any Cat work tool going on a Cat machine is to put them on the proper size machine for safety and stability of the configuration,” Munch said.

For the new rotary cutters, he said, the RC20 is intended for 20- to 34-ton excavators, and the RC30 fits the 28- to 50-ton excavators.

The rotary cutters are compatible with Cat hydro-mechanical work tool brackets, which allow operators to move more smoothly from one task to the next. In addition, the tools can be manually turned either 90 or 270 degrees and with an optional hydraulic lines kit, the rotary cutter can be turned up to 180 degrees for cleaning narrow trenches or working away from the machine to help increase productivity.

Unlike hydraulic hammers, the cutters can be used underwater without modifications to the tool or machine.

Overall, rotary cutters can be used in applications including trenching, profiling rock and cement walls, tunneling, quarrying, primary demolition, and underwater work.

“We’ve been in the hydraulic hammer business for 25 years, and yes, we’re very successful in that space,” Munch said. “We’re coming out with these rotary cutters because they have certain advantages.”

For example, he said, in a trenching application, a rotary cutter can cut a more precise narrow trench. Using a hydraulic hammer, a 10-foot trench is going to be V-shaped and about 25-30 feet wide. With a rotary cutter, the rotary drums are cutting or turning at about 85-95 turns per minute with 44 picks on each side.

A direct drive motor offers high torque, production, and performance to help operators get the jobs done faster. With less space between the drums, operators can build narrower trenches while also burning less fuel.

“With a rotary cutter, in a space-driven application where let’s say it’s an urban application so you don’t have the space to go 25 feet wide,” Munch said, noting that the rotary cutters deliver high performance in the right material.

However, the important distinction is that there is no intent to take the place of or eliminate hydraulic hammers or multiprocessors. During recent visits to multiple jobsites, Munch said nearly every location had both a hydraulic hammer and rotary cutter.

“They will start a trench with a Cat hammer get in so wide and then they will drop the rotary cutter in there leaving the profile of the trench where again, it’s not the big V shape,” Munch said. “It’s a very complementary tool, in the right application where space could be at a premium, even lower noise level, rotary cutters are a really good fit.”

A 320-size hydraulic hammer delivers about 126 dB noise level. The same-sized rotary cutter will have about 90 dB or lower.

Easy to maintain

With no greasing tensioning points, there is no daily maintenance on the rotary cutters Mechanical seals help to lock in grease and keep dust out to go longer between servicing. The built-in case drain filter helps to protect the hydraulic motor and pumps by preventing impurities from entering.

Using double support bearing on each drum, the motor shaft transmits only motion with no load to help keep the rotary cutter running longer. Quick access maintenance panels ensure peak operation is maintained.

Also, the rotary cutter picks are easily replaced with a simple tool and can be switched out quickly.

Other than maintenance on the rotary cutters themselves, the way the attachments break up material helps reduce wear on buckets removing debris from sites.

The tool mills the material being discharged from the trench without getting stuck between the housing and drum.

“It’s going to leave a very fine product that most if not all contractors will use that for backfill.,” Munch said. “Unlike some applications with hammers or multiprocessors, you need to move that material and transport it. The fewer times that you touch a product, the less fuel burned with machines moving it, the more productive you’re going to be.”

Lastly, when using multiple attachments at a site, it’s important to keep track of them. Cat attachments with asset tracking can be viewed within VisionLink alongside Product Link subscribed equipment. Attachments with an asset tracker send an alert if they leave an easy-to-setup site boundary to help keep tools more secure.

Quick Specs

RC20

- Weight: 2,954 lbs.

- Interface: Pin on, CPG, CW, S

- Carrier weight: 20-34 metric tons

- Operating pressure: 2,466-5,802 psi

RC30

- Weight: 5,159 lbs.

- Interface: Pin on, CPG, CW, S

- Carrier weight: 28-50 metric tons

- Operating pressure: 2,756-5,802 psi

Read the full article here