Photo courtesy of Bandit

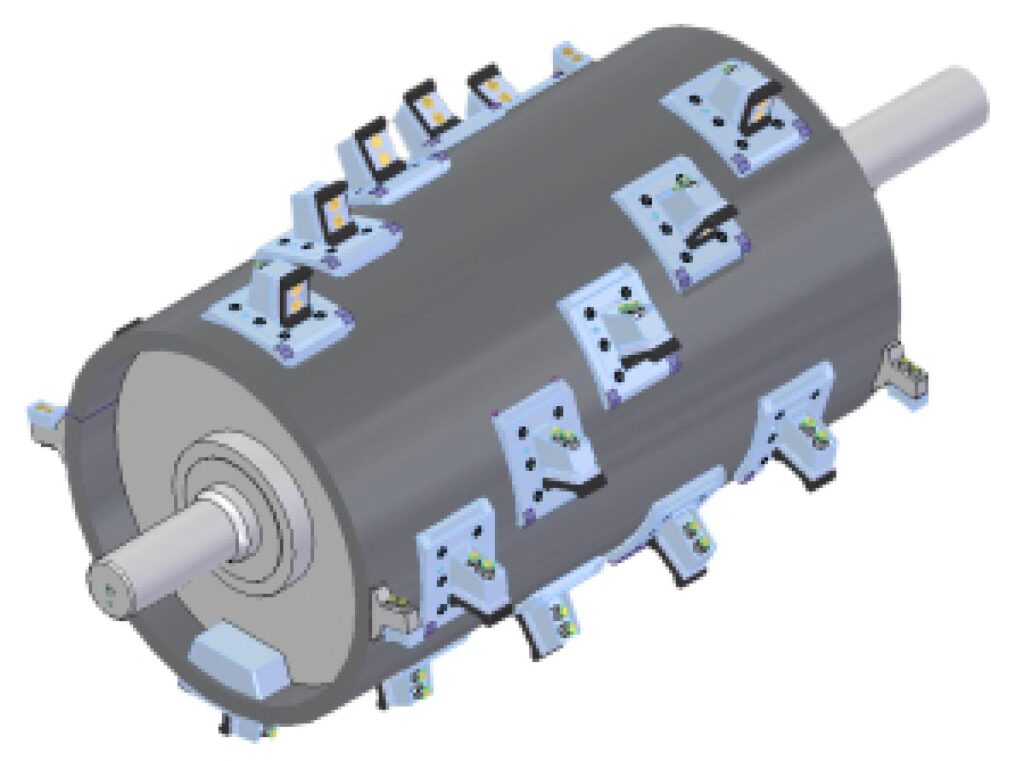

The heart of the HM6420 is a 50 in. diameter by 66 in. wide hammermill. The mill is equipped with 20 carbide infused hammer inserts built to withstand the toughest material fed into the machine.

The Bandit team has brought the HM6420 hammermill grinder to market.

This highly productive 40 in. capacity grinder is designed and manufactured to be an alternative solution for those grinding applications that may contain contaminants. A Caterpillar C32, 1,200 hp engine provides ample torque and horsepower for optimal machine performance and productivity.

The heart of the HM6420 is a 50 in. diameter by. 66 in. wide hammermill. The heavy-duty mill features a 1.75 in. drum skin custom formed from rolled plate. The mill is supported by a 7 in. main shaft constructed of alloy steel that has been ultrasonic tested.

Each pocket within the mill is manufactured from high strength A-514 steel. These combinations create a structural sound mill for added durability and integrity. The mill is equipped with 20 carbide infused hammer inserts built to withstand the toughest material fed into the machine. Each holder is securely attached to the mill via a quick change pocket system. Each holder recesses into the mill pocket, increasing durability.

A top plate covers the pocket and holds in place by six hex bolts. The hammer insert is attached to each holder utilizing two bolts. With this set-up, the mill hardware is easier and quicker to replace.

A heavy-duty slat-style infeed conveyor is directly driven generating more than 18,000 lbs. of pulling power. The large diameter feed wheel is also directly driven and provides an additional 17,000 lbs. of pulling power and 8,650 to 17,300 lbs. of down force when hydraulic pressure is applied. These combinations allow the HM6420 to grind massive quantities of material efficiently and effectively at one time.

A proportional feed system is standard and regulates the feed system from 82 to 132 ft. per minute. The HM6420 has one of the fastest feed rates on the market allowing it to quickly process material. The proportional feed system allows operators to adjust the feed based on material being processed ensuring maximum output and grinder efficiency, all while achieving a higher quality end-product.

Three screens are located on the top side of the HM6420 mill. A variety of screen sizes are available up to 7 in. to produce various end-product sizes. The top feed wheel moves upward, and a removable screen cradle allows for quick screen set-up changes. All work for screen changing is performed outside of the machine.

An impact detection system is standard and designed to limit damage if a contaminant is struck inside the grinding chamber. Once an impact event is detected, the grinder will idle down, open the gate, disengage the clutch, and reverse the feed.

A 56 in. dual discharge system with a stacking height of 16 ft. 8 in. is standard. The standard wireless remote controls all grinding and tracking functions and features an LCD screen that will display engine coolant temperature, engine oil pressure, engine load percentage, engine RPM, and battery voltage.

Bandit initially debuted the HM6420 at the 2023 ConExpo show. After the show, further evaluation and testing was conducted and the machine was then demonstrated to a variety of customers and dealers at Bandit’s 40th Anniversary event in September of 2023. Final testing of the HM6420 took place in the fourth quarter and the machine will begin production in the first quarter of 2024.

The addition of the HM6420 expands the already diverse line of Bandit horizontal grinders available.

For more information, visit banditchippers.com.

This story also appears on Aggregate Equipment Guide.

Read the full article here