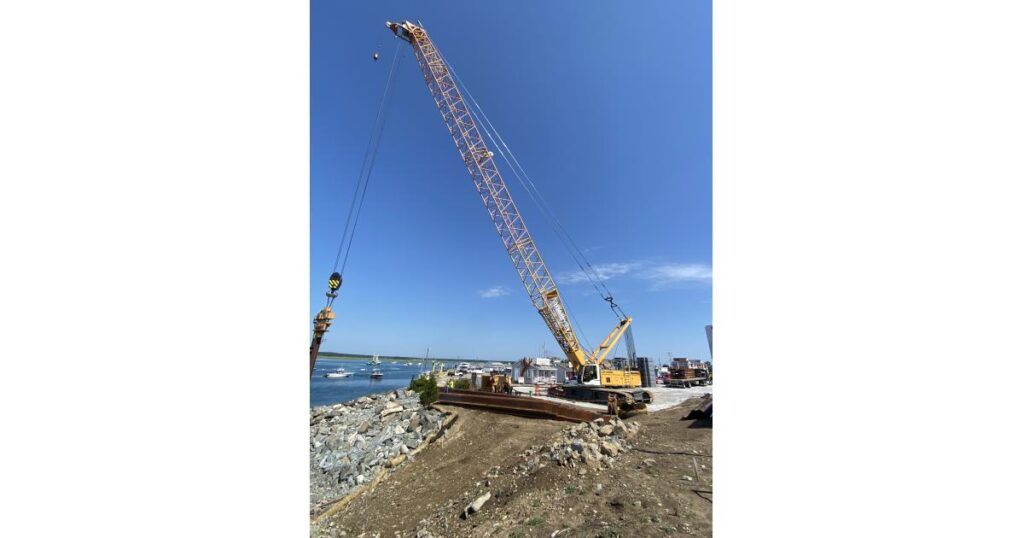

Photo courtesy of NHDOT

A crawler crane will be used to build the cofferdam.

Construction of the replacement of the Neil R. Underwood Memorial Bridge across the inlet of Hampton Harbor that spans Route 1A from Hampton to Seabrook, N.H., began in May.

SPS New England of Salisbury, Mass., is the lead contractor after offering a low bid of $107.5 million.

The long-planned project will be paid with 80 percent federal funds with the state’s 20 percent match coming from turnpike toll credits, according to Jennifer Reczek, a New Hampshire Department of Transportation bridge engineer.

The bascule bridge was built in 1949 and replaced a wooden bridge originally constructed for trollies and cars, known as the “Mile-Long Bridge,” according to NHDOT. It has been rehabilitated multiple times, in 1963, 1978, 1983, 1990, 2002 and 2010. Emergency repairs to the bascule span mechanical were undertaken in 2018.

According to SPS New England, the project will replace the State Red List Neil R. Underwood Bridge that carries NH 1A (Ocean Boulevard) over the Hampton River at the inlet to Hampton Harbor. The project limit begins on NH 1A in the town of Seabrook approximately 1,500 ft. south of the proposed bridge and continues northerly on NH 1A 3,900 ft. across the bridge to a point approximately 100 ft. south of the intersection with Ashworth Avenue in the town of Hampton.

Photo courtesy of NHDOT

The existing bridge is 1,193 ft. between abutments and consists of 13-spans with a moveable single-leaf bascule span in the center at the navigational channel. The bridge width is 26 ft. between curbs. The 150-ft.-wide federal navigational channel is reduced to 40 ft. as it passes beneath the movable bridge span.

“The proposed bridge will be a fixed high-level steel girder structure on a new horizontally curved alignment west of the existing bridge. The bridge will consist of seven spans and have a length of 1,300 feet between abutments. The bridge width will be 38 feet between two curbs [two 11-foot travel lanes and 8-foot shoulders] and include two 6-foot sidewalks with overlooks at Piers 2 and 5. The bridge will accommodate the full 150-foot-wide channel with a vertical clearance of approximately 48 feet. The improvements to the navigational channel will provide clearance for all regular waterway users, including U.S. Army Corps of Engineers dredging equipment that is currently too large to transit the existing bridge for the harbor channel to the west,” SPS New England said.

“Approach roadway improvements consist of full box reconstruction of NH 1A. A pedestrian walkway will be constructed in front of the abutment beneath Span 7 of the bridge that will connect Hampton Beach State Park to the Hampton State Pier property. The existing bridge will be demolished upon the completion of the proposed bridge replacement work.”

Dennis Switzer, a contract administrator of NHDOT, said the job started in May with utility relocation. Since then, workers have put in a temporary bulkhead for bridge access and an abutment cofferdam.

The Aquarion Water Co., Hampton, N.H., is assisting with the project. Amanda Keyes, the company’s manager of capital delivery, said, “Aquarion has two 4-inch water mains that currently lay under the Hampton Harbor that will be impacted by the work and removed from service as part of the bridge construction. Aquarion will be constructing a new 12-inch water main on the underside of the proposed bridge.

“During the duration of the project, which is anticipated to take three years, the Sun Valley neighborhood of Hampton, which is located just south of the bridge will receive drinking water through an interconnection with the Seabrook Water Department.”

The construction equipment being used by SPS New England in the project includes a Cat 328 hydraulic excavator, a Grove GRT 8100 all-terrain crane and a rubber tire excavator, according to Richard Arcand, a NHDOT spokesperson.

The key challenge of construction on the Hampton Seabrook bridge project, according to the SPS New England post, is water work restrictions.

“Water work is limited to time of year restrictions or working within cofferdams, which requires critical work to be potentially performed during non-ideal weather conditions.”

Read the full article here