FAE has introduced the PT550 to replace the PT475. The PT550 is a tracked carrier built for big challenges and is ideal for jobs in large, wooded areas and along oil and gas pipelines. This vehicle can work on large areas of soft, uneven, or swampy ground and can handle longitudinal slopes up to 45 degrees and transverse slopes up to 32 degrees, all with a low ground pressure of 13 psi.

The PT550 has updated many features compared to the PT475. The machine features design changes, technology upgrades, and a redesigned cab. The PT550’s Cat. 2 ROPS/FOPS/OPS-approved cab has a new configuration and an integrated cabin pressurization system. Other improvements for added operator comfort and productivity include Lexan glass windows, ergonomic joysticks, a pneumatic seat, a 10-inch touchscreen display to control operating functions, a 360-degree camera system and display, and a heated and refrigerated compartment.

The PT550 uses a Caterpillar C13B six-cylinder engine. The Tier 4 Final/Stage V engine delivers 536 hp and is equipped with a turbocharger with an aftercooler. The combined diesel particulate filter (DPF), selective catalytic reduction (SCR), and diesel oxidation catalyst (DOC) guarantee compliance with Tier 4 Final/Stage V. The PT550 is also available with a Tier 3/Stage III A engine for emission-free markets, rated at 475 hp. The 12.5-litre displacement and the electronically controlled proportional and reversible fan cooling system help for performing heavy jobs and inside tropical climates.

The FAE PT550’s undercarriage is designed to provide performance and reliability. The lubricated track chains last longer than conventional chains and provide a smoother ride. When combined with the dozer-type rollers and oscillating undercarriage technology, the PT550 offers grip and comfort. There are two roller guard options to adapt to different environments. The geometry means a low centre of gravity and ideal contact between the chain and the drive wheel, two fundamental elements that perform even on slopes. The FAE PT550 wheelbase also extends the load distribution area, which means lower specific pressure against the ground. The undercarriage frames are designed to withstand major stresses and make maintenance easier.

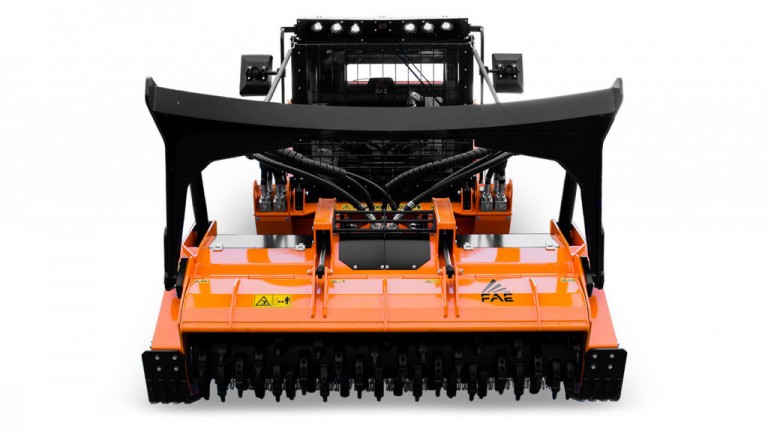

The PT550 can be equipped with a forestry mulcher or a multitask head to crush stone and till soil. Each machine benefits from Active Power Management technology, which combines the Floating System function with the Load Control function, ensuring that the head always follows along the ground and that power is managed during operation. Combined with the 300/U/SONIC and 500/U/SONIC forestry mulchers, FAE’s Sonic technology enables the head to work at ideal capacity at all times. Sonic technology adjusts the torque in real time according to the force required, for up to 30 percent higher productivity.

Read the full article here