Caterpillar’s seven ADT models are engineered for harsh job sites across the globe, including soft terrain and rugged haul roads. The EJ models include an ejector system that enhances productivity by allowing continuous material discharge without lifting the bed. Design priorities emphasize uptime, operator comfort, safety, and intuitive operation. Each truck is equipped with standard features that reduce operator input, such as assisted hoist, stability assist, and automatic retarding control. The next-generation 725, 730, 730 EJ, and 735 models add advanced technology, including dynamic rollover protection, auto wait brake, push-to-start ignition, LED lighting, updated keypads, and an optional object detection system with multi-view camera. These upgrades aim to improve operational safety, ease of use, and throughput in high-volume environments.

Features of the 730 EJ

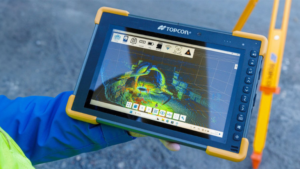

The Caterpillar 730 EJ uses a push block to unload without raising the bed, reducing tip-over risk and sticky carryback. This function helps maintain full capacity and saves 30 to 40 seconds per cycle on well-designed sites, boosting daily productivity. While spreading material on the move, dozer needs are reduced. Inside the cab, the next-generation 730 EJ upgrades the operator’s experience with a touchscreen pad, push-to-start ignition, operator ID, rollover protection, auto wait brake, overspeed protection via ARC, optional coaching, and better fuel efficiency.

See the complete ADT spec guide and find out how Caterpillar’s machines stack up.

Read the full article here